Machinery and Facilities

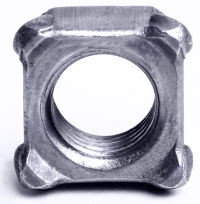

We use high-quality nuts in machinery parts as a component of our effective testing and inspection infrastructure. We are constantly working to raise the quality of our output and processes. We have a good inspection and testing facility that includes indicators and tools for measuring various fastener properties.

WIPL is dedicated to providing Quality Products to the Automobile and General Engineering Industries. We are a force to reckon due to our untiring commitment towards quality, service, and timely delivery.

- High-speed nut formers-Taiwan make

- Tapping Machines

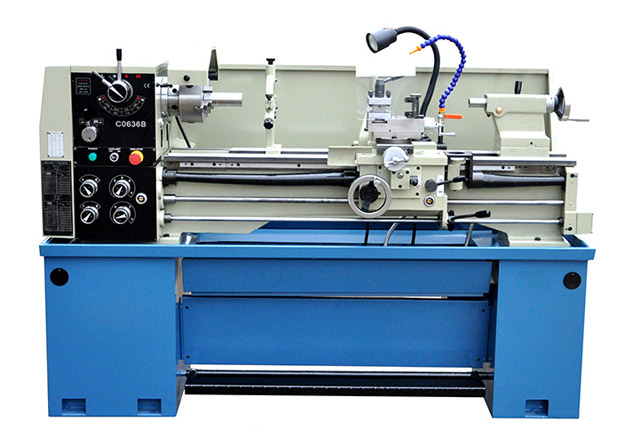

- EDM, Cylindrical & surface Grinder, Tool Cutters, Milling Machines, Lathes, etc.

- Utilities such as Diesel Generators & Air Compressors